Dellestraat 55

3550 Heusden-Zolder

Belgium

t. +32 (0)78 155 202

csoapsa@airproducts.com

More about our 5 major CO2mmitments to our customers

Our 5 major CO2mmitments which we make to our customers every day:

- Customers can always rely on us to do what we promise

- We are unconditionally dedicated to quality and safety in all we do

- Our pro-active innovation drive is to benefit our customers

- True respect for the environment lives in all we do

- We act respectful and socially responsible

1. Customers can always rely on us to do what we promise

We do everything possible to make sure a customer always gets their delivery. We know that a non-delivery of CO2 could lead to production disruption and huge related costs for you.

Here is a list of what we have in place and which measures we take to achieve this day after day:

- We have 8 independent plants and 4 sites based on 6 independent sources

- We always give priority to direct customers

- We have a 5-day buffer stock

- In addition, we have an extra buffer as our sources have rail connections

- We have our own means of transport

2. We are unconditionally dedicated to quality and safety in all we do

Our dedication to quality and safety is unconditional.

Our focus on quality can be summarised in the following 3 key areas:

- Rigorous quality assurance programme

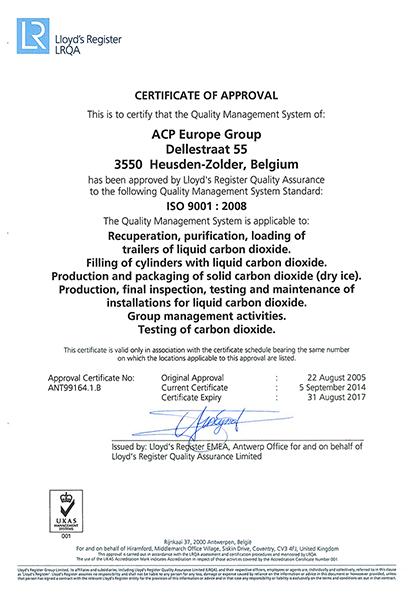

- Entire vertical process certification of all ACP plants

- Safe For Food quality

We were the first company to receive FSSC 22000 certification from LRQA (LLOYDS) and the first gas company certified worldwide. This is proof of our trendsetting behaviour when it comes to quality.

Furthermore, all production units are ISO 9001 and FSSC 22000 certified.

|

|

|

In 2013, ACP received the Coca-Cola Best Supplier of the Year Award.

ACP’s quality assurance programme ensures that we meet all the European legislation requirements, as well as the more detailed composition requirements set by the European industrial gases companies (EIGA) and the beverage industry (ISBT).

Safe For Food

ACP developed its own Safe for Food quality programme.

ACP’s Food-Grade Quality Programme conforms to the European Industrial Gases Association (EIGA) and the International Society of Beverage Technologists (ISBT) regulations, and consists of:

- State-of-the-art purification processes

- Online quality monitoring and management in our production units

- Regular analyses of final products, carried out by ACP and independent labs

- Strict loading and unloading procedures

- Rigorous traceability

Safe For Food +

In co-development with some key customers, we went even further, beyond the already demanding requirements of the EIGA and ISBT regulations. In order to serve these customers even better, we developed a Safe For Food + programme with guaranteed 99.99% purification and the most stringent safety system:

- Guaranteed 99.99% purification

- Quality diagnosis/sample analysis

- on every production day

- of every single trailer shipment

- Analysis of every single delivery

- Sealing of every freight shipment

- Separate logistics flow to avoid any risk of contamination

- Individual seals are used to prevent product tampering

Dedicated to safety and health for our customers, our customers’ customers, our employees and society in general

Safety and health are absolutely key for ACP.

Despite its somewhat harmless character, dangerous situations can occur when CO2 is used carelessly or when large quantities of CO2 are accidentally released. Human or mechanical errors can cause a high presence of CO2 in the ambient air. Carbon dioxide is odourless and colourless. CO2 snow can cause freezing symptoms and inhalation of CO2 can lead to dizziness and asphyxiation.

Carbon dioxide is heavier than air. If the installation is located on lower floors (basements) or in enclosed spaces, forced ventilation is necessary to remove the gas.

All relevant safety information is available in the safety data sheets.

- Deeply refrigerated liquefied carbon dioxide safety data sheet

- Pressurised, liquefied carbon dioxide safety data sheet

- Solid carbon dioxide safety data sheet

ACP applies very strict safety measurements for the design, placing and maintenance of its installations. These rules are based on international guidelines, legislation and good practices.

All installations designed and placed by ACP meet the Guidelines of the European Parliament and the Council of the European Union of 29th May 1997 concerning pressurised equipment. These relate to pressurised vessels, installation piping, safety fittings, etc.

3. Our pro-active innovation drive is to benefit our customers

Our own engineers and technical team are dedicated to CO2 and all kinds of CO2 applications. Since 1897, we have acquired extensive expertise and have developed several patented technologies.

ACP’s innovation projects are all directly linked to our customers’ needs with immediate benefits in terms of increasing operational excellence and/or reducing our customers’ total cost of ownership.

4. True respect for the environment lives in all we do

All ACP’s production plants are 100% based on recuperating CO2 emissions from the production of ammonia or bioethanol. ACP does not use "underground CO2 sources" or CO2 generated by the combustion of fossil fuels.

In our own production chain, we focus constantly on energy and water reduction (such as compressors with variable frequency drive, recovery of wastewater as top-up water). We have invested in a modern trailer fleet with reduced fuel consumption.

ACP helps to decrease worldwide CO2 emissions:

- For many years, ACP has been active in developing applications in which CO2 is removed from the atmosphere in a sustainable way.

Examples:

- Use of CO2 as a raw material for the production of methionine (food for animals)

- Use of CO2 for the neutralisation of wastewater (formation of carbonates)

- Use of CO2 for the production of PCC (precipitated calcium carbonate)

- Use of CO2 in the carbonisation of slags and other wastes

- Use of CO2 as an addition in greenhouses, where it helps in plant photosynthesis

- Use of CO2 for polymer production

- ACP has developed other applications in which its “recycled” CO2 replaces techniques that are a lot more polluting and contribute to CO2 emissions:

Examples:

- Use of CO2 as the cooling medium in transport cooling, the Ice Shuttle Programme

- Use of CO2 for compost cooling and transport cooling

- Developing highly efficient (low energy, integrated energy) tailor-made evaporation solutions at the customer’s site

- Cleaning with Dry Ice blasting, thus avoiding contaminated water and sand

- ACP has invested in refining CO2 sustainably from bioethanol fermentation sources (Carboheim), in which the CO2 is recuperated from plants. ACP also has CO2 purchase contracts with green biogas units.

- ACP’s shareholders have invested in massive tree plantation projects in South America.

- ACP has calculated its carbon footprint and is currently having it verified and validated by a recognised third party. ACP will draw up action plans to decrease its carbon footprint in the near future.

- ACP has taken part in research projects aimed at reducing the use of fossil fuels:

- Use of CO2 for algae growth and its further transformation into fuels and biochemicals

- Use of CO2 as an extraction medium, replacing oil-derived hydrocarbons

- Use of CO2 as a medium in truck cooling systems instead of chlorofluorocarbons

5. We act respectful and socially responsible

Social responsibility is one of ACP's core values used to measure its performance. ACP's policy is concerned with human rights, working conditions, the environment, social commitment and development. It is based on the seven principles of sustainable development and the ISO 26000 guidelines.